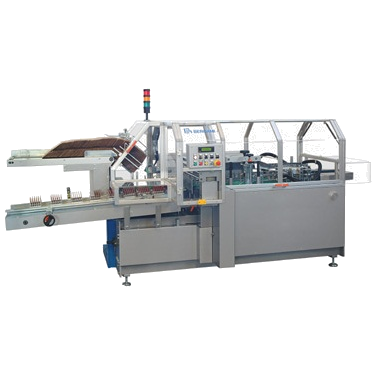

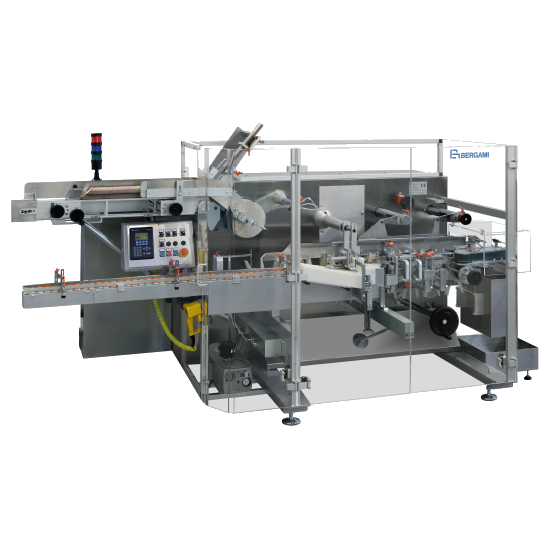

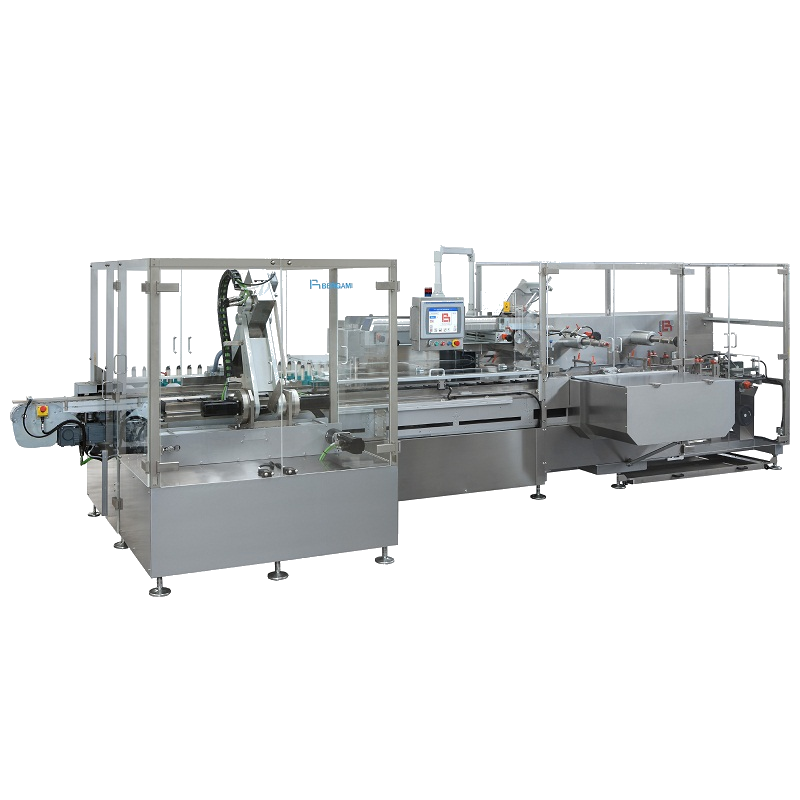

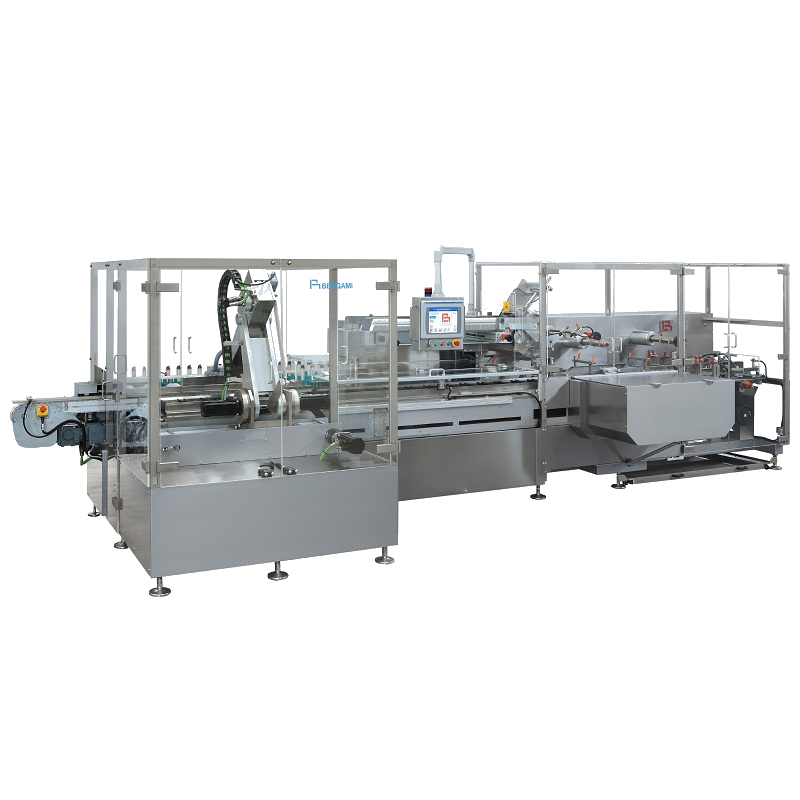

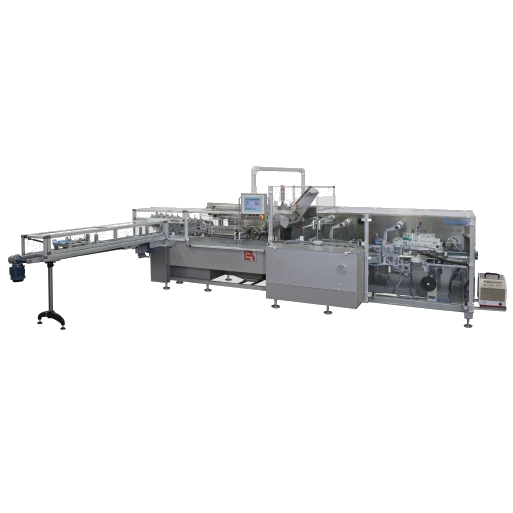

Horizontal intermittent motion cartoner specifically designed for medium/large size products cartoning applications. This machine is suitable for the pharmaceutical, cosmetic, food and consumers products industry.

- Bucket feeding chain into which, by means of dedicated feeders, the products are placed automatically to be cartoned. One sensor checks product presence in the bucket and calls the correspondent carton and leaflet (if necessary), enabling the sensors of correct retrieval;

- Carton erection is carried out by the traditional double vacuum arm for positive opening system, which guarantees optimal operations with the widest range of cartons and cardboard quality;

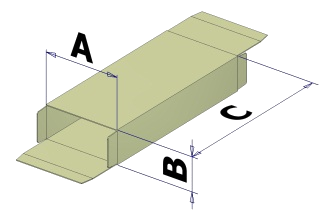

- Carton transport system centrally adjustable;

- Widening of the belt transport system performed with hand wheel and digital indicators to suit carton length (“C” dimension);

- Product arriving from the infeed chain is inserted with a pusher placed on the operator side;

- After the closing operation, lateral belts discharge the carton;

- The touch screen operator interface control panel shows all the machine functions and displays the machine status, as well as fault/alarm messages;

- The speed is set from the control panel and allows the adjustment for the optimal production speed;

- Machine is built thinking first about its mechanical sturdiness, with no hydraulic or oleo-pneumatic devices, in order to guarantee a great reliability and duration.