Automatic horizontal KP15 Casepacker-Palletizer combining in a single, compact, monobloc the operations of packing products in cases then palletizing them. Compact, ergonomic, reliable and sturdy, it is innovative and versatile thanks to the use of robotized solutions which significantly enhance performances in terms of speed and flexibility. The palletizing operation is managed through the Machine HMI, a high performance, extremely versatile device. Thanks to a dedicated version, it allows the use of two palletizing/depalletizing stations at the same time. While one station is operating, the pallet can be changed in the other. There are many options available, for a wide range of customizations: possibility of installing printers, labellers, barcode scanners, check weighers.

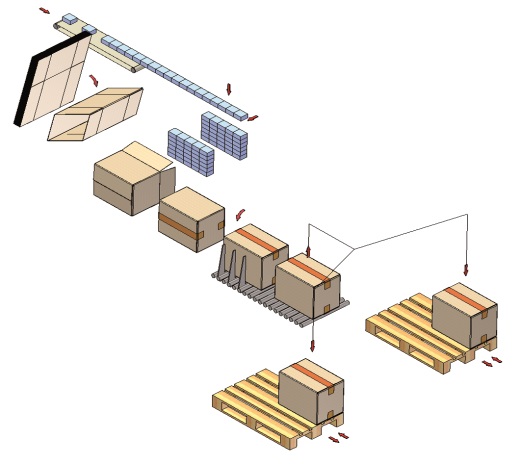

- The case is fed into the magazine, located in an ergonomic position on the side of the machine;

- All operations are fully automated, performed by brushless motors and controlled by an Industrial PC;

- The case is picked up and transferred to the opening unit by a double arm equipped with suction cups, holding it from side and bottom, and thus guaranteeing a perfect squaring;

- The products arriving from the infeed belt, are grouped, vertically stacked inside the hopper and finally pusher into the case;

- Servodriven lugs transfer the case to the flap folding and taping area;

- The robot picks up the incoming cases and places them on the pallet, according to a pre-set pattern;

- Automatic Palletizer arranged with single or double floor pallet station;

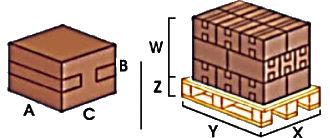

- Human interface both for diagnostic and creation of pallet pattern;

- Quick size changeover;

- Optimal visibility during the whole packaging process;

- Automatic end-of-batch machine emptying