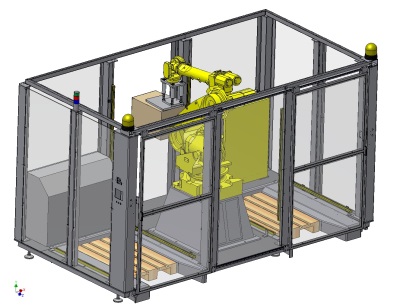

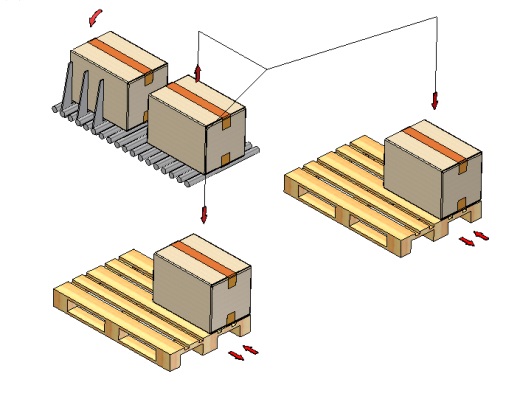

The P 15 has been developed to respond to the market requirements for flexibility and compactness of the palletizing section of the modern production lines. The heart of the machine is the robot (4 or 6 axis, according to the application) which picks up the incoming cases and places them on the pallet, according to a pre-set pattern already stored in the machine memory.

Ultramodern robot technology that is in operation thousands of times throughout the whole world guarantees top machine availability and low life-cycle costs over the entire productive life of the machine.

The machine can be equipped with large capacity and empty pallet magazine with automatic handling of empty and full pallets. Products can be fed from single or multiple lines. Due to its modular design, the pallet handling section can be customized according to the requirements of the end user.

The machine can be supplied as a stand alone unit or connected to a BERGAMI side loading case-packer, particularly where space is at a premium.

The machine also features a standard PLC unit which interacts with the robot processor, thereby making operation straightforward. A large and comprehensible operator interface makes change-overs simple and assists with diagnostics. The machine is fully guarded by transparent panels interlocked with safety switches and light curtains in the pallet removal area.

- Uses both US and European type pallets;

- Fanuc robots for placement;

- Automatic Palletizer arranged with single or double floor pallet station;

- Human interface both for diagnostic and creation of pallet pattern;

- Quick size changeover;

- Optimal visibility during the whole packaging process;

- Automatic end-of-batch machine emptying;

- The touch screen operator interface control panel shows all the machine functions and displays the machine status, as well as fault/alarm messages;

- The speed is set from the control panel and allows the adjustment for the optimal production speed;