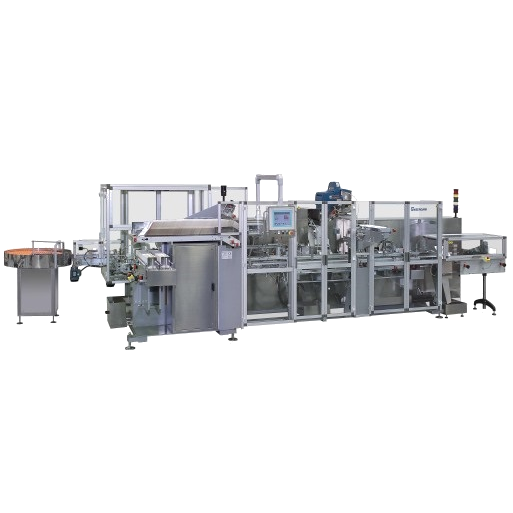

Fully Automatic vertical intermittent motion cartoner specifically designed to meet the demand of a rapidly increasing cosmetic market especially for the cartoning of products such as creams, lotions and perfumes.The intermittent motion vertical cartoner ASV 120 is designed with the modern “Balcony” construction that makes it possible to completely separate the mechanical zone from the carton and product conveyor zone to thoroughly inspect the cartoner internal and, eventually, detect and clean batch products at the end of the production run. This allows complete accessibility, for cleaning, maintenance, inspection and size changeover operations. It’s built in a very ergonomic way, making operator’s interventions as easy as possible.Latest ergonomic features (operator friendly), cartons, liners, leaflets, coupons, spatulas and other eventual components can be easily manually loaded from the front or back of the machine.The product can be fed to the machine with or without the use of pucks, and it is inserted into the carton by a Bergami Pick and Place system model BRUTUS.

- Balcony construction, as per GMP rules;

- Compact dimensions;

- Maximum visibility for the whole process, thanks to completely transparent guards;

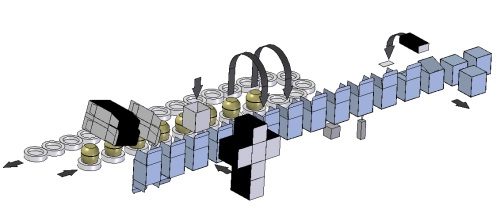

- The carton is picked from the horizontal magazine, rotated and inserted directly into the carton transport system, which operates in a positive way;

- Carton transport with 8 timing belts centrally adjustable with hand wheels and digital indicators to suit carton Width, Length and Depth (“A”,”B” and “C” dimension);

- No contact with metal rails due to the fact that the transport belts travel with the carton;

- Particularly low noise and Lubrication free thanks to advanced solutions adopted for product and carton conveyors;

- After the closing operation, lateral belts discharge the carton;

- Touch screen control panel, for operator interface and machine management;

- Self-diagnosis and help functions;

- The carton transport system consists of scratch-proof white plastic toothed belts to insure package integrity, even when processing cartons with a high gloss finish. The ASV 120 cartoner is ideal for handling fragile or delicate products including cartons with internal liners;

- Very short change-over time;

- Maintenance free;

- Superior precision in picking the product;

- Soft handling during the insertion operation avoiding any possible damage.