Bergami enters the modular tray/cartoner market with focused pricing!

Available in several pitches, and for speeds of 40, 80, or 120 cartons/min, the FA60 can form cartons, display cartons or trays from a flat blank. Automatic loads products [...]

New Bergami Palletizer Model P15

Bergami is proud to announce the latest addition to our world class line of secondary packing machinery, the new Bergami P15 Palletizer. The Bergami P15 was born out of [...]

New Bergami Tube Filler Model TF 200

Bergami announces the latest addition to their Tube Filling and closing Systems the model TF200. Designed with the new “in-Line” approach and orbital track which accepts empty tubes vertically [...]

Fully integrated servomotor control feeding system for constant motion cartoning systems

Bergami raises the bar on constant motion cartoning with the announcement of their fully integrated constant motion servo control system for the automatic loading of bottles, jars, tottles, products [...]

Special package for vials and ampoules

BERGAMI has succesfully installed the cartoner model ASV60 Pharma for the packing of Vials and Ampoules with inner protection partition at ASTRAZENECA Plant in Milan. Total protection of the [...]

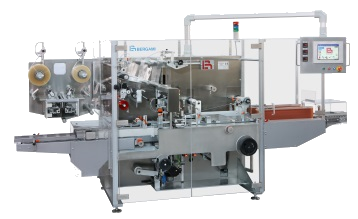

Bergami has successfully installed at L’Oreal the new wrapper CX5

Bergami has successfully installed at L'Oreal the new wrapper CX5.