The new ASV60 Pharma is a result of the latest technologies available, with strong attention focused in answering the growing GMP requirements in today’s market place. is suitable to handle a variety of pharmaceutical products as ampoules, vials, syringes and carpules including integrated partition pre-formed or from flat blanks.

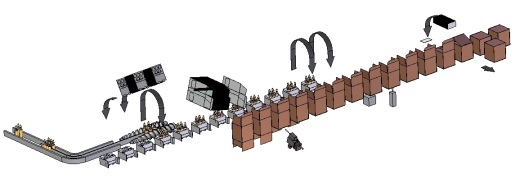

The partitioned cartons, trays and packs are formed automatically from pre-glued cartons or a pre-glued cartons and a flat blank. The products are either fed from a fully automatic filling/labelling line or from cassettes, with automatic collation and inserting of the items in corresponding packaging, using vacuum technology for product protection.

The advantages of the packaging solution:

- Lower cost of packaging (from 10% to 35%) with respect to thermoformed tray inserted into a carton

- Possibility of standardization of the pack external dimensions, according to the different types and size of carton vial housings, therefore with quick change-over times to other format – and product sizes

- Single machine of reduced overall dimensions that require only one operator

- Total protection of the pack: vials and ampoules are held in place in the insert housings and secured at both neck and body, without any contact with the upper and lower side of the carton

- Low environmental impact

- Cardboard double layer on case sides, single opening with possibility of tamper evident closure (glue or marked label)

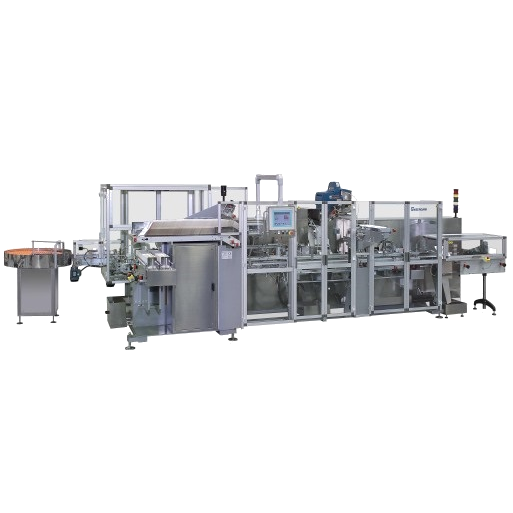

- Balcony construction, as per GMP rules;

- Maximum visibility for the whole process, thanks to completely transparent guards;

- The carton is picked from the horizontal magazine, rotated and inserted directly into the carton transport system, which operates in a positive way;

- No contact with metal rails due to the fact that the transport belts travel with the carton.

- Particularly low noise and Lubrication free thanks to advanced solutions adopted for product and carton conveyors

- Touch screen control panel, for operator interface and machine management;

- Self-diagnosis and help functions;

- The carton transport system consists of scratch-proof white plastic toothed belts to insure package integrity, even when processing cartons with a high gloss finish. The ASV 60 cartoner is ideal for handling fragile or delicate products including cartons with internal liners;

- Very short change-over time;

- Maintenance free

- Superior precision in picking the product

- Soft handling during the insertion operation avoiding any possible damage