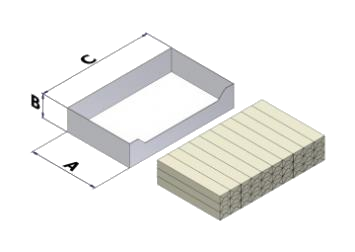

The AS70 WA is a tray forming and filling machine suitable for all demands of pharmaceutical, cosmetics and food industries, that can be supplied with various feeding systems. The “wrap-around” customized forming system realized on the product, allows for no space between the product and tray. The open construction frame allows a wide access to the working area as well as extremely simple and comfortable maintenance. The work plane height amount between 800 and 900 mm

- All feeding groups are located in ergonomic position, in order to make the loading easy for the operator;

- One sensor checks product presence at the infeed and calls the correspondent carton and leaflet (if necessary), enabling the sensors of correct retrieval;

- Blanks are positively picked-up from the magazine by a vacuum arm for a positive forming procedure, which guarantees optimal operations with the widest range of trays and cardboard quality;

- Trays transport system centrally adjustable;

- Widening of the belt transport system performed with hand wheel and digital indicators to suit carton length (“C” dimension);

- Product arriving from the infeed system is inserted with a pusher placed on the operator side;

- Product introduction on the tray with “NoTray-NoPush” device;

- Flap gluing with hot-glue injection device;

- After the closing operation, lateral belts discharge the tray;

- The touch screen operator interface control panel shows all the machine functions and displays the machine status, as well as fault/alarm messages;

- The speed is set from the control panel and allows the adjustment for the optimal production speed;

- Machine is built thinking first about its mechanical sturdiness, with no hydraulic or oleo-pneumatic devices, in order to guarantee a great reliability and duration