Available in several pitches, and for speeds of 40, 80, or 120 cartons/min, the FA60 can form cartons, display cartons or trays from a flat blank. Automatic loads products by single or multiple servo pick-and-place system that can load products of nearly any orientation, including cartons, bottles, vials, ampoules, pouches, tubes, etc. Products may be loaded vertically, either in a singular method or pre-collated, grouped and/or stacked in any fashion. Balcony design assures cleanliness and ease of access. Mechanical drives and machine movements provide for seamless and quiet operation with low maintenance.

The FA models stands for versatility and can be used for a variety of products and carton types. Food, pharmaceutical, consumer, confectionery or tobacco products can all be reliably packed into a carton/tray/display.

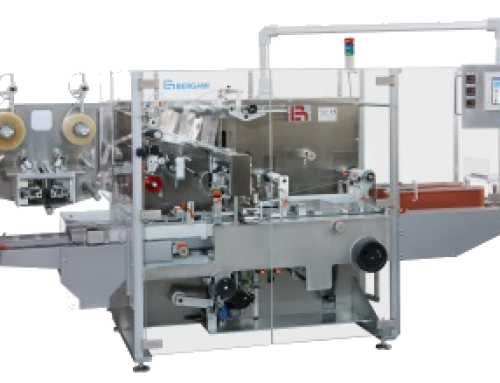

The FA packaging machine is a monobloc with “Balcony” construction. Making it a highly flexible, clear and easy to access to the machine with outstanding operating simplicity. The modular design allows for different versions of trays, wrap-arounds or cartons with lids. Many combinations of these configurations is also possible.

Thanks to the flexibility of the FA cartoner, the manipulation of product collation and their insertion into a carton can be achieved with Top Loading or Side Loading capability. Starting from a flat blank that is picked-up from a magazine, filling it with the product(s) and, as a final step, closing it in one of the various options, depending on the packaging style needed.

Like the other models from BERGAMI, the FA cartoner has a minimum overall dimension; it uses accurate mechanical and servo driven movements and reliable product feeding systems. Size change-over is very quick and simple; it is carried out with adjustments made through digital indicators positioned on the front of the machine.

The competitive advantages of the FA models

- Trouble-free alignment of blanks

- Protective handling of products

- Tray packer and wrap-around cartoner with lid closing obtainable on the same machine

- Suitable to handle products with irregular shapes at a high speed

- Flexible filling patterns (Top Load or Side Load)

- Maintenance Free

- Reliable packaging result

- Economic use of resources

- Excellent price-performance value

Optional Groups

- Several closure configurations available (Tuck-in Flaps, Glued Flaps, Tamper Evident, etc.)

- Leaflet or Object Insertion

- Wide selection of printing systems (Embossing, Ink-jet, Laser and others)

- Possibility to integrate Bar Code Readers and Complete Vision System

- Automatic reject of incomplete cartons

- Automatic feeding systems tailored according to the specific request